Since its inception in 1965, dental implant technology has successfully helped millions of patients worldwide regain their radiant smiles, significantly improving their quality of life. These artificial teeth not only look natural but also function just like real teeth and are long-lasting. The core of dental implant surgery lies in using a screw-like implant, made of metal, to replace the missing tooth root. A prosthetic crown, carefully designed to mimic the appearance and function of a natural tooth, is then placed on this solid foundation, making it nearly indistinguishable from real teeth. This solution is an excellent choice for patients seeking an alternative to ill-fitting dentures or bridges. Especially when natural tooth roots are insufficient to support traditional restorations, dental implants become an indispensable option. With dental implants, patients can enjoy their favorite foods and smile confidently without feeling any difference, achieving a remarkable leap in both functionality and aesthetics.

What Are Dental Implants?

A dental implant is a tiny metal device that is surgically inserted into the jawbone. It is often composed of titanium or another biocompatible material. Its primary function is to restore the lost tooth’s root structure and provide a strong foundation for subsequently placed restorations like crowns, bridges, or dentures.

The purpose of implants is to induce osseointegration, sometimes referred to as osseointegration, with the surrounding bone tissue. This is a biological process wherein the implant’s surface immediately forms a permanent and long-lasting relationship with the bone tissue. Similar to the roots of natural teeth, this osseointegration enables the implant to endure the stresses produced by chewing and other oral processes.

Three components make up dental implants:

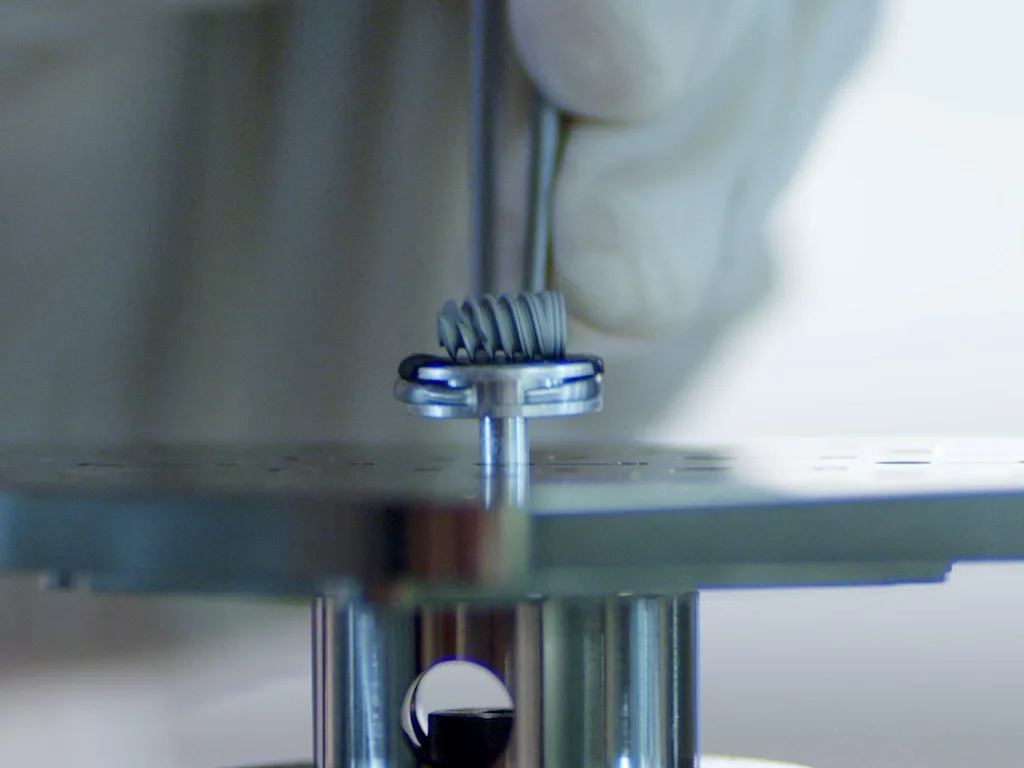

- Implant: The primary component of the device that is inserted into the mandible is this. Typically, it has a threaded or cylindrical shape to enhance osseointegration by expanding the area of contact with bone tissue.

- Abutment: The implant and top restoration (like a crown) are joined by the abutment, which is the central component. It offers a platform to support and secure the restoration and is often fastened to the implant using screws or glue.

- Restoration: This is the part of the implant that is visible and generally a bespoke crown that replaces the lost tooth’s look and functionality. All-ceramic, metal-ceramic, or all-metal restorations are available, depending on the patient’s requirements and preferences.

Dental Implant Materials

Titanium:

Currently, the most common material used for dental implants. Due to its excellent biocompatibility, titanium bonds well with bone tissue, forming a strong osseointegration. Titanium implants are not only highly durable but also corrosion-resistant, with a long service life.

Titanium Alloy:

Titanium alloys, such as TA4G, consist of titanium combined with other metals like aluminum or vanadium, which further enhance its strength and durability. It also boasts excellent biocompatibility and is the preferred material for many high-end implants. DentalMaster dental implant specifically uses Grade-4 Cold-Working Titanium.

Zirconia:

Zirconia is another material used for implants, primarily for patients allergic to metals. It has a color similar to natural teeth, making it more aesthetically pleasing, and is often used in cases with high cosmetic demands. While zirconia also offers high biocompatibility, its strength is slightly lower compared to titanium.

The Manufacturing Process of Dental Implants

The production of dental implants is a highly precise and technically demanding process that combines modern materials science with advanced manufacturing techniques. The following are the main steps in the manufacturing process of dental implants:

- Raw Material Preparation: Dental implants are typically made from high-quality titanium alloys or pure titanium, materials known for their excellent biocompatibility, high strength, and corrosion resistance. These properties ensure that the implant remains stable in the oral environment for a long period.

- Design and Modeling: Computer-aided design (CAD) software is used to create custom implant designs based on the patient’s specific oral conditions, such as the height, width, and density of the alveolar bone, as well as the treatment plan developed by the dentist. This personalized design ensures that the implant is highly precise and tailored to meet the unique needs of the patient.

- Manufacturing Process: High-precision 3D printing technology is employed to transform the CAD-designed model into a physical implant, improving the accuracy and efficiency of production while reducing material waste. After 3D printing, the implant undergoes further surface treatments (such as sandblasting or acid etching) to enhance its bonding capability with bone tissue. Additionally, thread processing is carried out to improve the implant’s stability and retention.

- Quality Control and Inspection: Every stage of the manufacturing process involves strict quality control to ensure that the product meets industry standards and patient requirements. Before being used clinically, the implant undergoes a series of tests to evaluate its biocompatibility, mechanical performance, and corrosion resistance.

- Sterilization and Distribution: Once the implant has passed rigorous quality inspections, it is sterile-packaged to ensure cleanliness and sterility during transportation and storage. Finally, the implant is delivered to medical institutions, where it is surgically placed by qualified dental professionals based on the specific needs of the patient.

Characteristics of Materials Used for Dental Implants:

- Biocompatibility: Titanium and zirconia both have excellent biocompatibility, allowing them to bond closely with human bone and promote osseointegration. This enhances the stability of the implants and reduces the risk of the body rejecting the implant, ensuring long-term success.

- Enhanced Strength and Durability: Titanium alloys (such as TA4G) retain the advantages of titanium while incorporating metals like aluminum or vanadium, further increasing the material’s strength and durability. Dental implants made from these alloys can withstand chewing forces and various stresses in the oral environment, ensuring long-term stability even under high loads.

- Aesthetic Appeal: Zirconia is ideal for aesthetically demanding implant restorations due to its natural tooth-like color. Zirconia implants offer a more natural appearance, particularly suitable for the anterior region, while still providing relatively high mechanical strength to meet both functional and aesthetic needs.

Conclusion

Dental implants are made of titanium or other biocompatible materials to restore the root structure of missing teeth and provide a solid foundation for restorations such as crowns, bridges, or dentures. The main function of an implant is to induce osseointegration, a biological process where the surface of the implant forms a permanent and lasting relationship with the surrounding bone tissue. The manufacturing process includes raw material preparation, design and modeling, 3D printing, quality control and inspection, and sterilization and distribution. Titanium and zirconium oxide are known for their biocompatibility, enhanced strength and durability, and aesthetics. These materials are ideal for aesthetically pleasing implant restorations because of their natural tooth color.